Energy Saving Inverters on Hydraulics

Electric motors driving hydraulic pumps are in common use in industry today. They provide motive power to machines using rams to move and hold machines in position. When the oil flow to the rams is not required, the hydraulic pump will continue to operate and the oil is then diverted around the circuit back to the tank by a pressure relief valve. This wastes energy and heats up the oil. In this case, inverters can save energy and help to keep the oil cool. It is not unusual to employ oil coolers to remove this wasted energy.

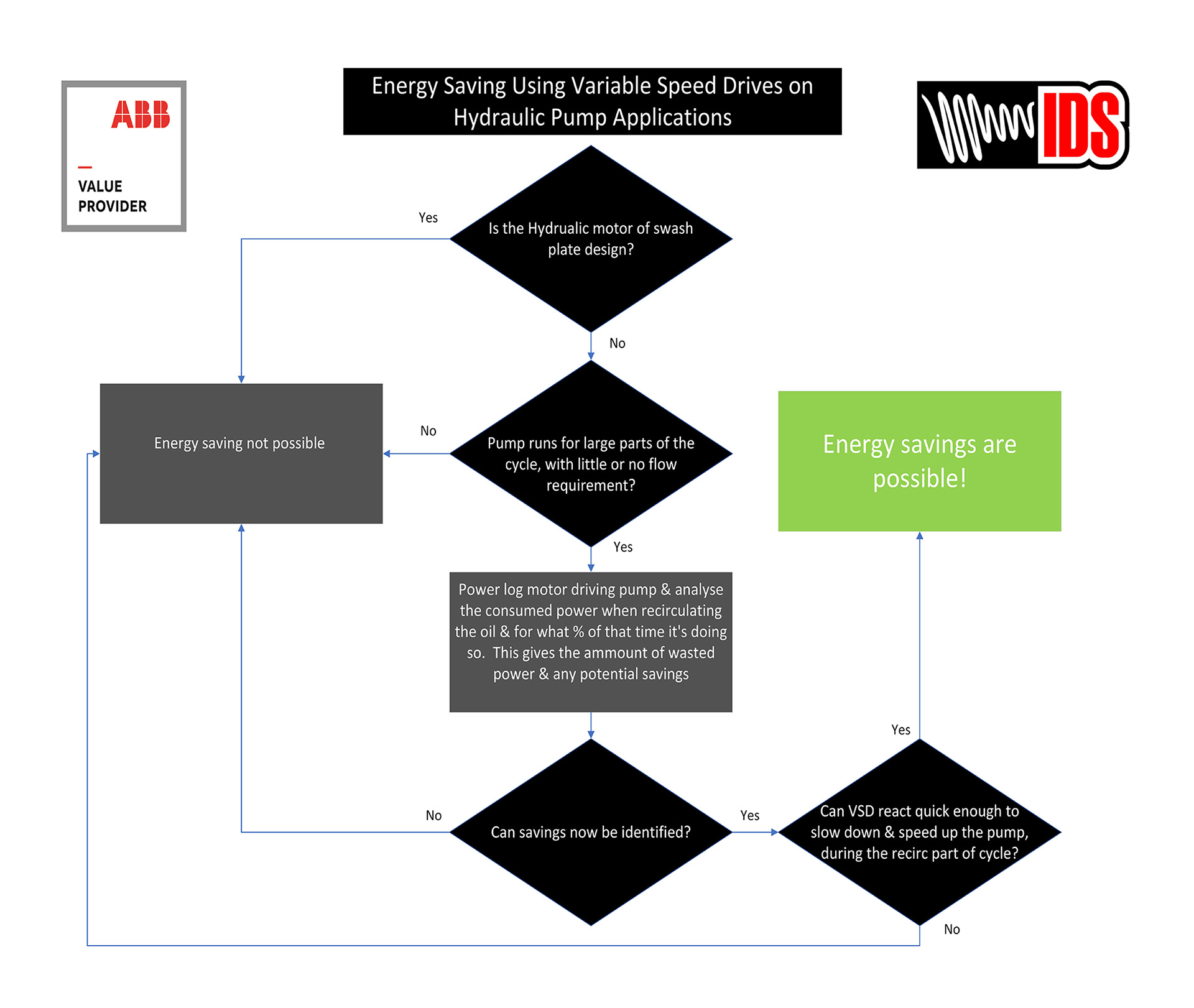

But deciding whether an inverter is suitable for energy savings on hydraulics is not as straight forward as, for example, on a pump or a fan. The steps to follow are as follows:

- Is the hydraulic motor a swash plate design? These are not usually suitable for inverter control. If no, go to 2.

- Is the hydraulic pump running for significant parts of the hydraulic cycle with little or no flow requirement? If yes go to 3.

- Power log the motor driving the pump and analyse the power consumed when recirculating the oil, and for what percentage of the time it is doing so. This then gives the amount of wasted power and the potential savings. If this proves to be financially viable go to 4.

- Can the inverter react quickly enough to slow down and speed up the pump during the recirculation part of the cycle? If so, then inverters can be used to save energy.

Energy Saving Inverters on Hydraulics

The next consideration is the control method, and this will depend on each individual machine. Very often the control is a two-speed operation – high speed when the flow is required and low speed when it is recirculating. Sometimes, the slow speed can be ‘off’ which saves the most energy, making use of the multiple motor starting available from inverters without overheating the motor.

The Benefits of Inverters on Hydraulics are:

- 20% – 30% energy saving.

- Reduced mechanical work done by the hydraulics leading to longer plant life.

- Cooler oil (the oil coolers will also do less work).

- If the hydraulic machine is left running when not required, inverter control can sense this and automatically send the system to sleep saving more power.

Working with IDS

At IDS we have worked in partnership with ABB for over 20 years. During that time, we have helped our customers to save energy on a variety of applications including hydraulics. Why not give us a call on 0115 944 1036 or email [email protected]