6 Reasons to Choose SynRM

The synchronous reluctance motor (SynRM) has been around for nearly a century, and yet it is only in recent years that it has become commercially viable as a high efficiency alternative to the induction motor. ABB’s Dave Hawley explains some of the benefits.

6 reasons to choose SynRM

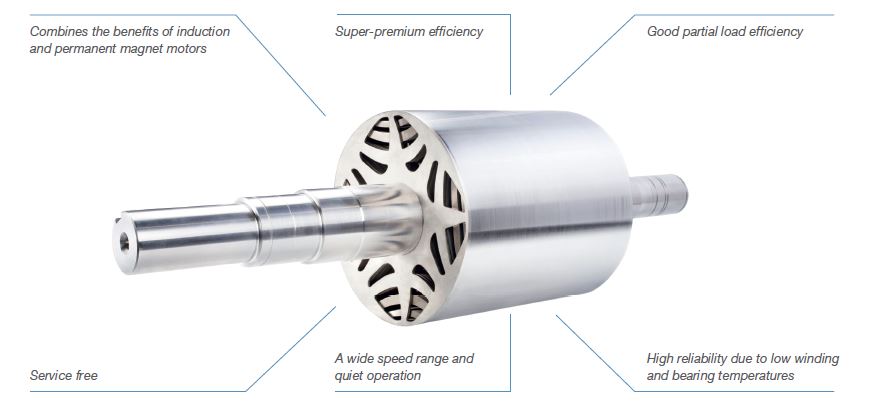

The core idea of a synchronous reluctance motor (SynRM) is that the rotor has no windings or magnets, just electric steel plates stacked together to form a rotor package. Unlike in an induction motor, a SynRM rotor has no induced current and thus no losses. This makes SynRM the perfect combination of simplicity and efficiency.

1. Full motor control, down to zero speed

Many processes require accurate speed control. SynRM is a synchronous motor that always runs at reference speed with practically no error, without an encoder. Even the best slip compensation systems in an induction motor inverter will never match the precision of SynRM. Sometimes an application may require a motor to run at slow speeds, for example at less than 40 rpm. If you are using SynRM and your drive cannot provide the necessary torque, it may trip. This means you may have downtime while the problem is being debugged. ABB drives provide full control and torque down to zero speed, even without speed sensors.

2. For all applications

This is important if you are planning on using the motor with applications other than quadratic torque applications like pumps and fans. The drives provide full SynRM motor control for constant torque applications such as extruders, conveyors and wire drawing machines.

3. Cool and quiet motor

The SynRM package where the motor and the drive are designed to work together brings two major benefits. The less noise your motor produces, the better the working environment. The SynRM motor runs very quietly compared to an induction motor due to the rotor geometry and the DTC technology of the ACS880 industrial drive. Heat means lost energy, but it also means that you need to cool your workspace to compensate for the heat produced. As the rotor geometry of SynRM has no rotor currents, the rotor losses, which in induction motor can add up to 40 percent of the total loss, are eliminated. Reduced losses mean better efficiency, a longer bearing lifetime and less dissipated heat losses from the motor.

4. Wide selection of drives

Processes are different, and each has its own demands for the drive. That’s why ABB offers a selection of drives with voltage range from 230 to 690 V and a power range up to 710 kW. You can order optional application programs with your drive. These programs are designed to support adaptation to various applications like artificial lifting, winders, cranes, cooling towers, etc. In addition, drives have built-in adaptive programming support based on IEC 61131-3 PLC logic that can be used if no suitable program is available.

5. Verified package efficiency statements

The efficiency of the motor and drive at different operating points is very useful information. This helps you estimate energy use when combined with your own overall machine efficiency. This is the focus of the new European standard 50598-2. IE4 packages fulfil the IES2 efficiency class defined in EN50598-2. With ABB’s SynRM package, you will always get a motor and drive that are dimensioned to work together efficiently.

6. Perfect for retrofits

The SynRM package is a perfect solution for motor retrofits. The IE4 SynRM is the same size as an IE2 induction motor, eliminating the need for mechanical modifications. The increased efficiency will, on the other hand, reduce the payback time of the investment.