Reactive Pump Controller

CONTROLLING THE THICKNESS OF SLUDGE AT SOURCE

Abstract

Primary and co-settled sludges are commonly removed from settlement tanks using timed, pumped, auto-desludge systems that are neither sensitive to the variable flux of settleable influent material nor sense the thickness of the sludge removed, resulting in thin sludge being produced which requires significant thickening before digestion and are expensive to transport by road tanker. The patented reactive pump controller, developed by IDS, senses the sludge thickness by monitoring the torque of the desludge pump’s motor. A simple calibration of torque against %DS allows desludging to be stopped when sludge becomes too thin with a >30% reduction in sludge volume demonstrated without compromising PST performance.

Within Anglian Water increasing the thickness of sludge exported from STWs by 1.5%DS represents substantial savings.

Keywords

Desludge optimisation, pump torque, sludge thickness, tankering, reactive pump controller

Introduction

Anglian Water serves the east of England, a region that covers 20% of the land area of England and Wales with over six million customers. To treat the wastewater produced, Anglian Water has over 1100 sewage works diffusely spread sites across the region. These sites produce 2.2million m3 of sewage sludge per year which has to be transported by road tanker to one of nineteen sludge treatment centres. This poses obvious logistical challenges and significant transport costs.

The sludge tankers are usually provided by Anglian Water’s Road Tankering Service. These can carry 29m3 of sludge and use HACH Solitax probes to record the thickness, or percent dry solids (%DS), of the sludge. Data from each collection is added to a central database giving a picture of the volume and thickness of sludge produced at each sewage works. A review of this information showed the average dry solids content of transported sludge to be 2.7%(Anglian Water 2012), the rest is water. This figure includes all kinds of sludge; primary, secondary and co-settled. Metcalf, Eddy (2003) state that primary and co-settled sludges can be removed from the PSTs at 4-6% dry solids. Achieving an average of 4%DS could reduce the volume of sludge transported across the Anglian region by up to 33% (~700,000m3). However, a proportion of the sludge transported is produced in small extended oxidation plants with no primary settlement; outside the scope of this work.

Optimising Removal of Sludge from Primary Settlement (PS)

Primary settlement aims to remove readily settleable solids from the wastewater treatment stream. It does this by introducing screened sewage and returned liquors in to the PST at a low velocity and turbulence which allows gravity to settle the solids to the bottom of the tank (Metcalf, Eddy 2003). A key part of the process is efficiently removing the blanket of settled solids (sludge), as if left in the tank too long it risks creating an anaerobic environment in which gas is produced, causing the settled blanket to rise. A rising sludge blanket can increase the solids content of the PST effluent, raising the strength of the settled sewage treated by the secondary process and causing a deterioration in final effluent quality (Metcalf, Eddy 2003).

The sludge removal process is known as desludging and can be performed by opening a valve at the base of the PST or using a pump to remove the sludge. The use of an automated pumped system is increasingly common as sites are visited less frequently. The desludge pump is usually controlled by a timer system which starts the pump at set times and for a set period of time each day; for example five pumps a day for fifteen minutes each. The lengths and timings of these pumps are calculated using the flow rate of the desludge pump and estimating the amount of sludge needing to be removed daily, but given the negative impacts of inadequate sludge removal they are often operated conservatively, leading to the production of thin, low %DS sludge. Preventing the production of this sludge would:

- Increase the on-site sludge storage capacity.

- Reduce transport costs and resultant emissions.

- Lower downstream thickening costs.

- Reduce the production of high strength decanting liquors returned to the treatment process.

Reactive Pump Controller (RPC)

This system uses a standard ABB inverter to control the desludge pump’s motor. The pump is operated at a constant speed while the built in, automatically generated motor model measures the % of maximum torque that the desludge pump’s motor is producing. As the sludge thins, its viscosity drops, causing the torque applied to the motor to fall. If this relationship between %DS and %torque is strong enough it should be possible for the RPC to monitor the thickness of the sludge being pumped and ensure the pump stops before the sludge gets too thin. This process has been patented by the inventors, IDS.

Method

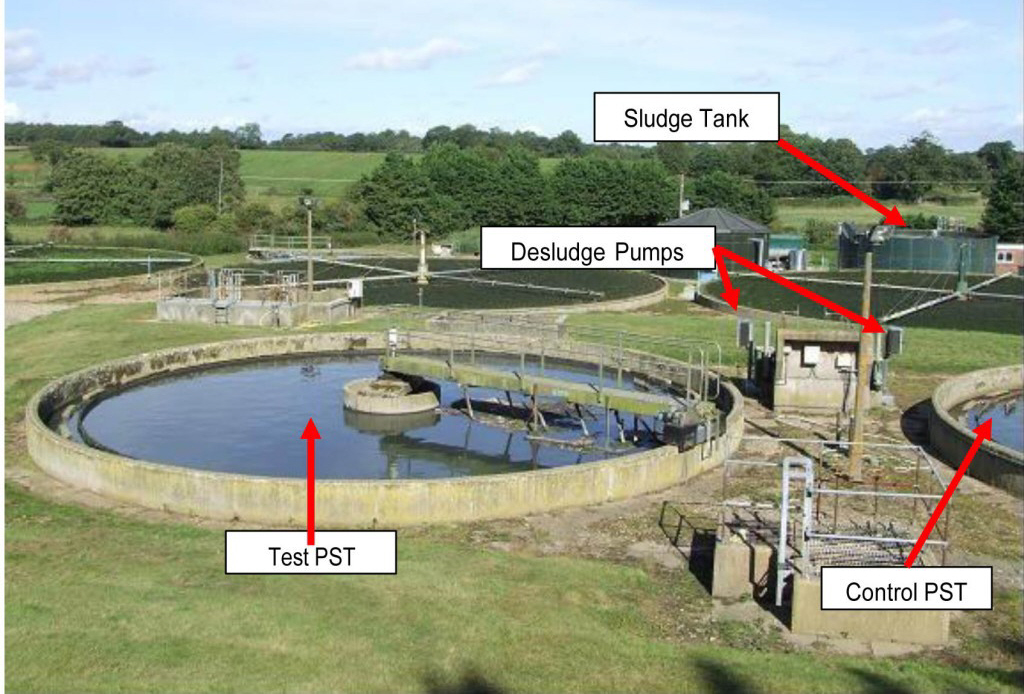

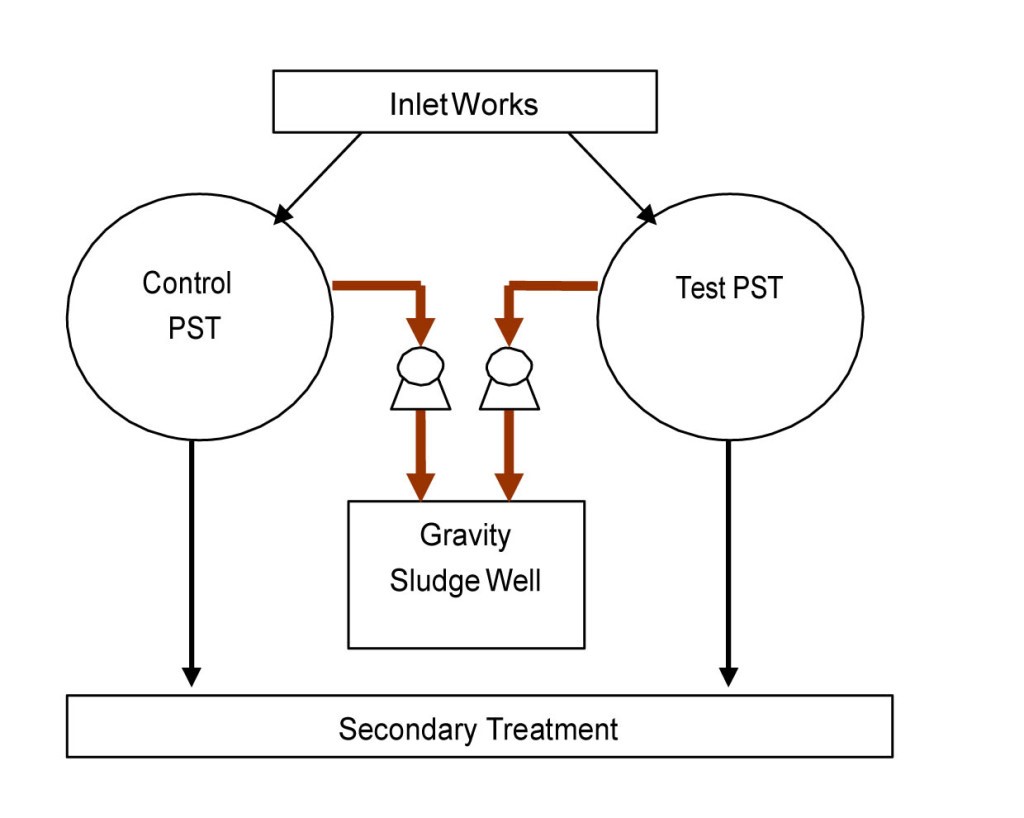

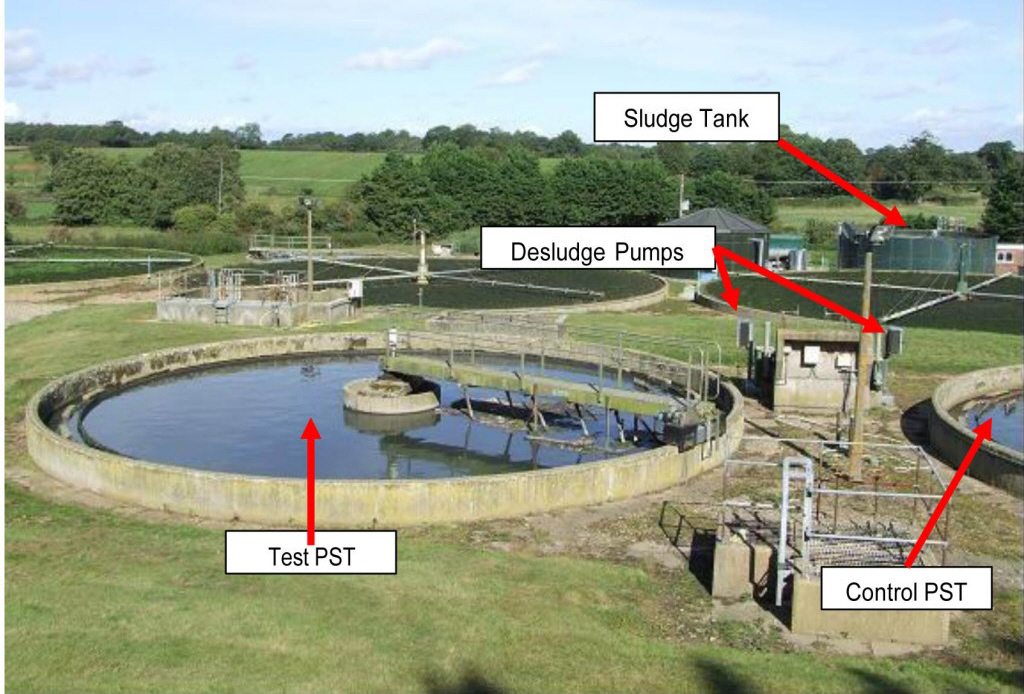

Given the positive results obtained in the initial tests relating diaphragm pump motor torque to sludge thickness a trial unit was installed on one of the PSTs on a TF works of 8000 PE, Figure 1. The site has two independent circular PSTs, each with its own diaphragm desludge pump feeding the sludge into a sludge wet well, from where it flows under gravity to the sludge holding tank. This arrangement allows the desludging of one PST to be controlled by the RPC unit with the other left with its original timer clock control.

The trial was conducted from the 14th of September 2011 to the 23rd of February 2012.

Trial Aims

- To confirm a relationship between pump motor torque and sludge thickness.

- To quantify any improvement in sludge thickness the RPC can reliably produce from the PST.

- To measure the impact removing only thick sludge has on the PST sludge blanket level and settled sewage quality.

Data Collection

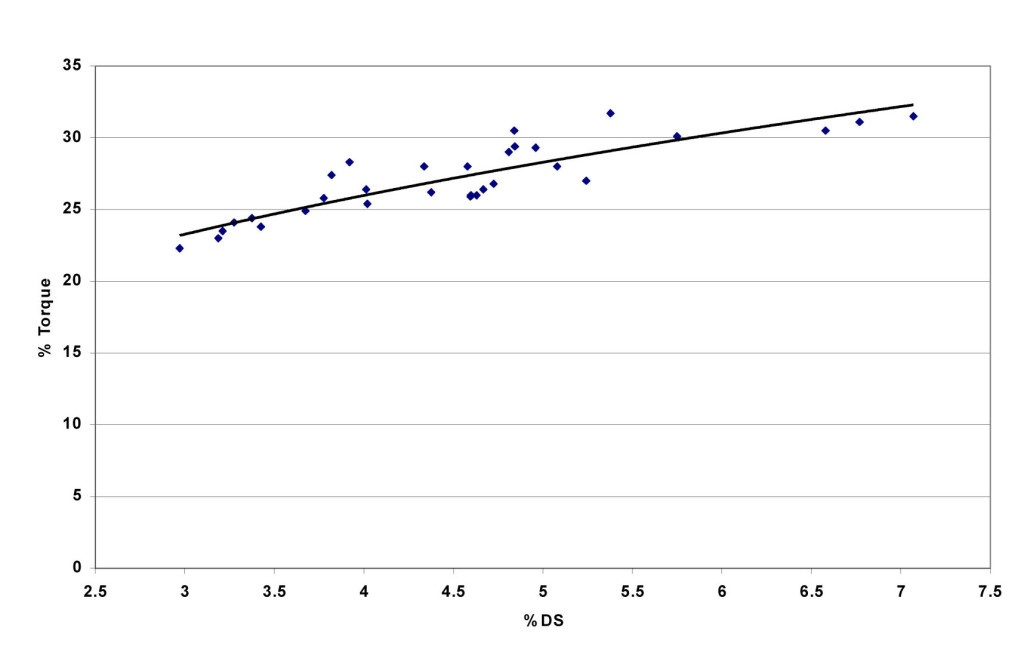

Torque data: A data logger was used to record pump torque at 10sec intervals during each desludge. *It should be noted that due to technical difficulties the logger was not working until 19th of October when the torque set point was increased for the first time. The calibration curve (Figure 4 ) was used to infer sludge thickness from the pump torque.

Sludge thickness (%DS): When a team member was on site, sludge spot samples were collected with a bailer during desludge cycles and the pump torque recorded. Sample buckets were permanently hung below the sludge discharge point from each pump, to collect samples of sludge representative of the sludge in the last few minutes of desluding. The thickness of these sludge samples was determined by comparing the wet weight of 10ml of sludge to its weight after drying in an oven at 105 OC for 24hrs. All other sludge thickness data was inferred from the pump torque data using the calibration curve (Figure 4).

Sludge blanket depth: A Sludge Judge was used to take depth reading at four equally spaced points in the sludge hopper, using the circumference of the inlet shroud as a guide. An average of these readings was used for each datum.

Settled Sewage TSS(mg/L): One litre samples were collected from each PST effluent drain and 100ml filtered using a 0.45micron filter paper. The dry weight of the solids captured was then measured after drying in an oven at 105 OC for 24hrs.

Figure 1: Primary settlement tanks and desludge pumps at the trial site.

Figure 2: Flow sheet for primary treatment and sludge removal at trial site.

Results

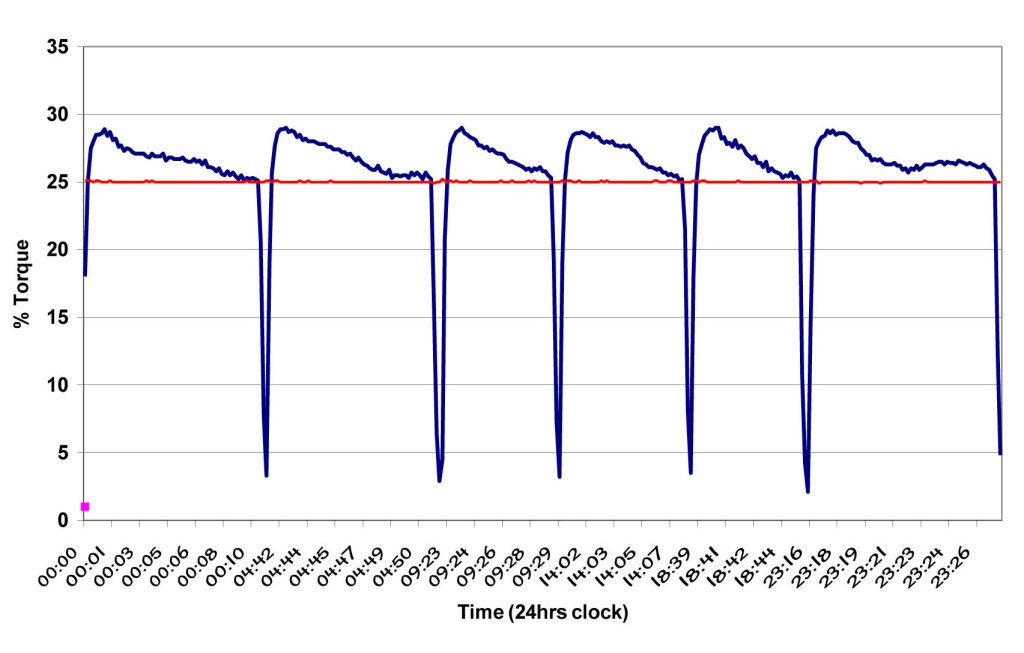

Figure 3 shows some typical recordings of pump torque during the six desludge cycles per day, with the minimum torque set-point at 25%.

Figure 3: Desludge motor torque profile for diaphragm pump; set-point at 25%

Figure 4 shows the torque and dry solids readings collected during desludging cycles on six separate days between October 2011 and September 2012. The pump was operated on hand with no torque inhibit.

Figure 4: Diaphragm pump calibration; % of maximum torque against sludge thickness

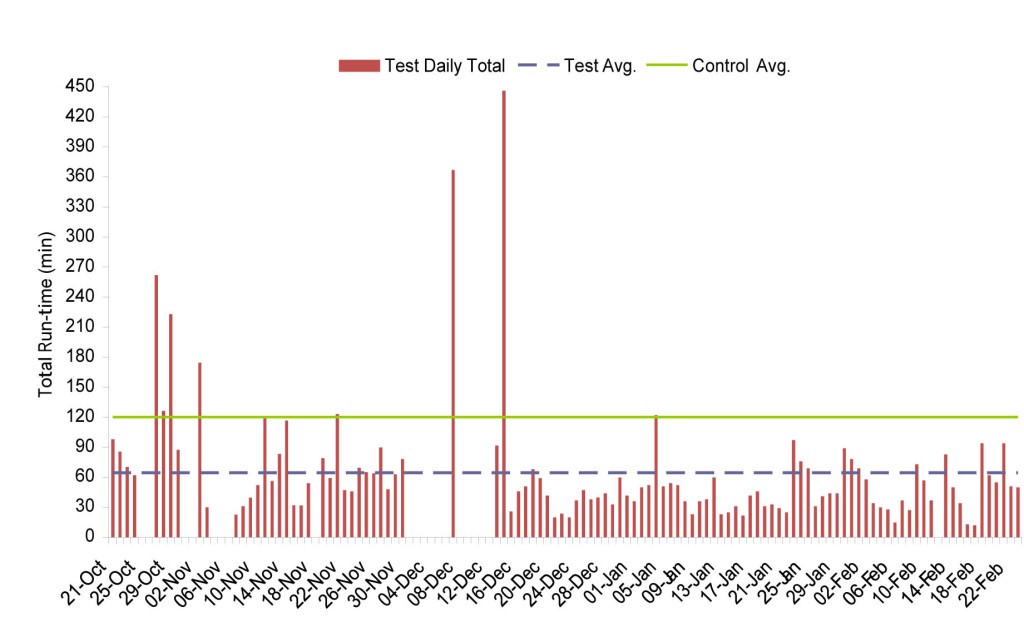

Figure 5: shows the total daily run times recorded by the data logger. It can be seen that the test pump ran for an average of 65min/day as compared to 120min/day on the timer controlled control PST; a reduction of 46%. The gaps seen in the data are due to the sludge storage tank being full; inhibiting the desludge pumps.

Figure 5: Total daily run time for the test desludge pump.

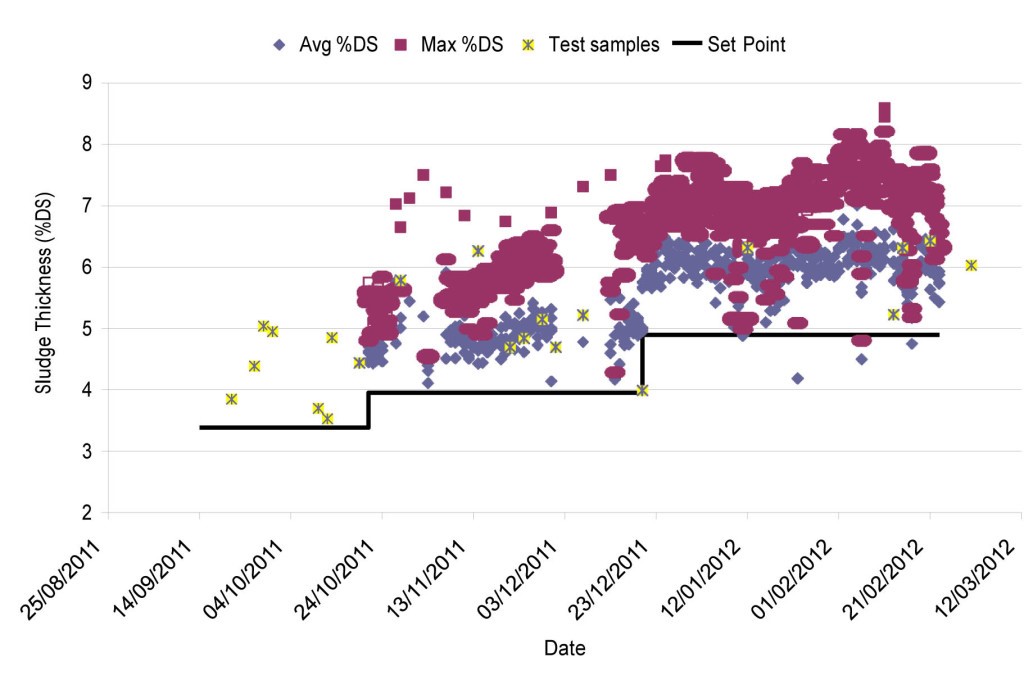

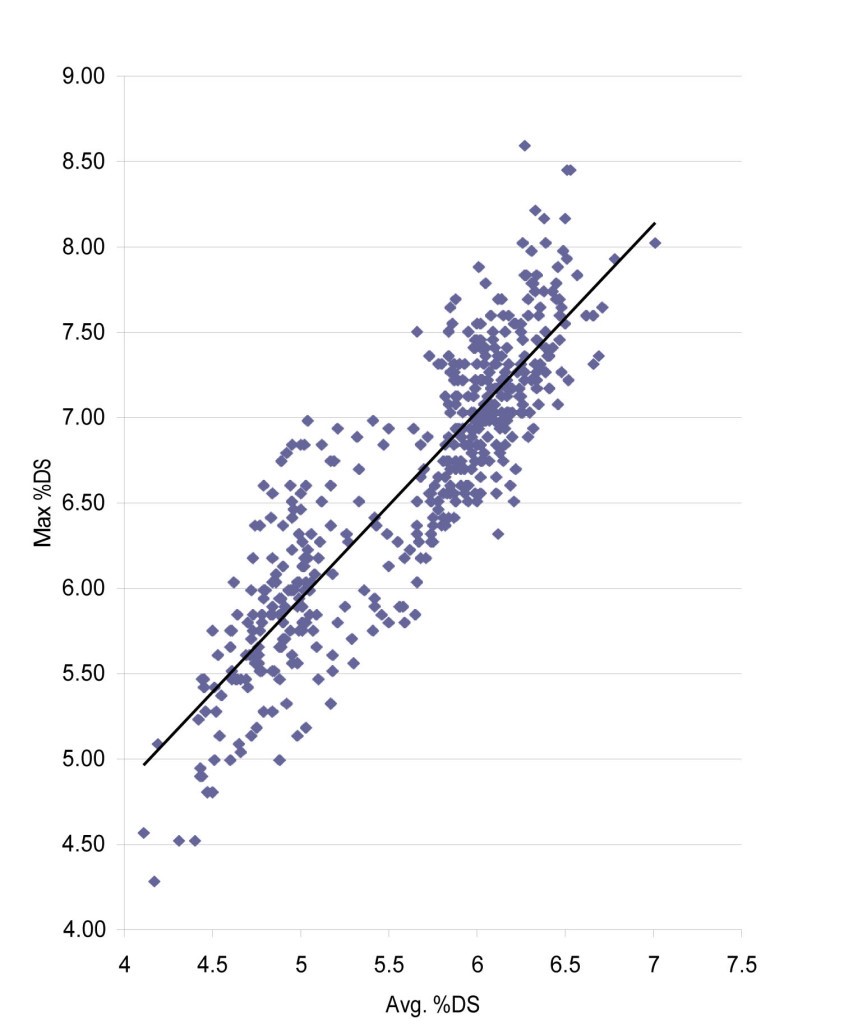

Figure 6 and 7 shows that the average and maximum thickness of the sludge removed from the test PST increased with the RPC’s torque set-point. The spot samples taken also show a good agreement with the average sludge thickness.

Figure 6: Average, maximum and spot sample sludge thickness and minimum torqueset-point.

Figure 7: Average and maximum sludge thickness for each desludge cycle.

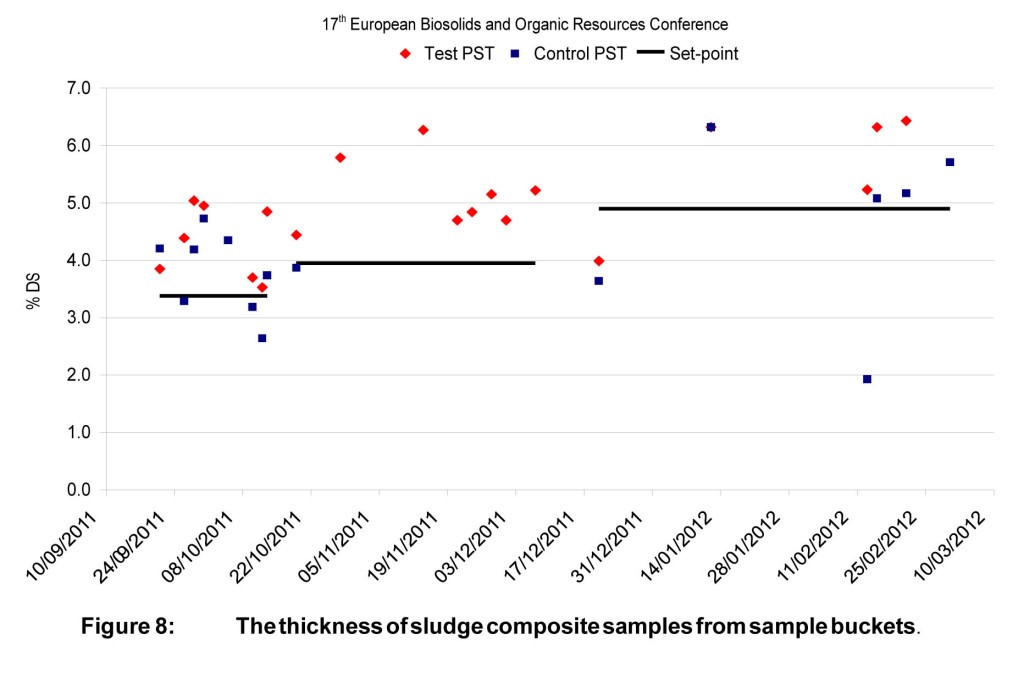

Figure 8 shows the thickness of the sludge samples collected from the sample buckets. The sludge from the test PST is thicker than that collected from the control PST (0.8%DS on average) and increases with the torque set-point.

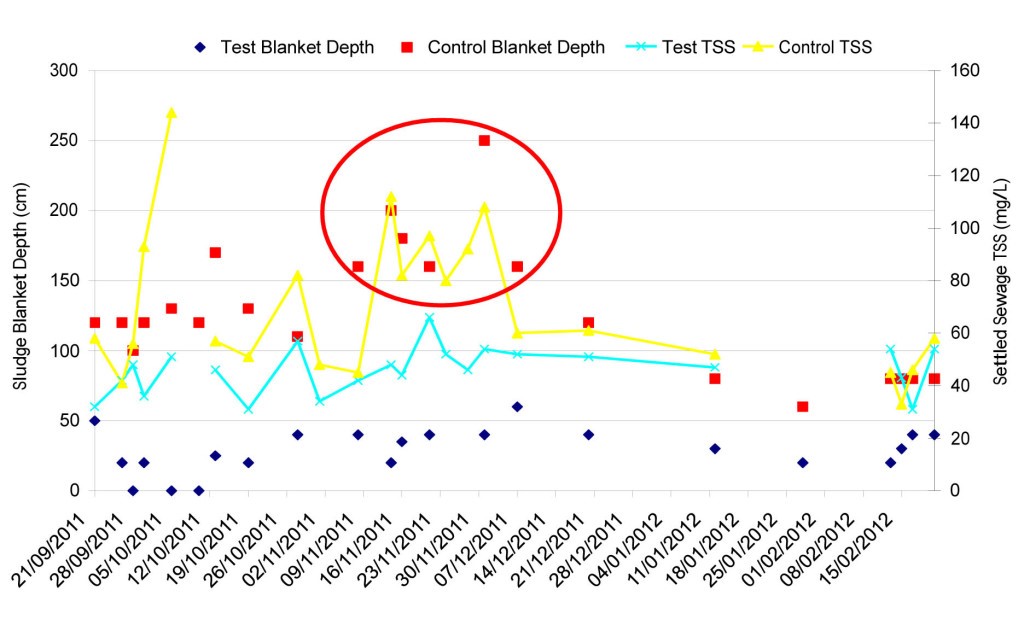

Figure 9 shows the sludge blanket depth and settled sewage suspended solids in each PST during the trial. The test PST started with a lower sludge blanket level and PST effluent TSS than the control PST. This difference was maintained throughout the trial with no significant deterioration in sludge blanket level or PST performance, despite the average sludge thickness rising to 6%DS for the last two months of the trial. An ANNOVA test (p-value of 0.136) showed that the effluent TSS did not change significantly as the set-point was raised. The control PST did see a deterioration in PST performance (data circled on Figure 9) but this was due to the failure of the desludge pump’s motor and insufficient manual desludging. Once this problem was resolved the data follows the same trend as for the test PST. This period of poor PST performance highlights the importance of ensuring sufficient sludge removal.

Figure 9: Sludge blanket depth and settled sewage suspended solids.

Discussion

Pump motor torque can be related to sludge thickness with diaphragm pumps.

Figure 4 demonstrates a good correlation (regression co-efficient of 0.8) between pump motor torque and sludge thickness. This level of accuracy is thought to be sufficient to control the removal of sludge from PSTs as if the pump stops slightly early in one pump or slightly late in another the PST‘s performance is unaffected as long as on average the correct amount of sludge is removed. However PST performance will be affected by consistently stopping the desludge cycle too early, so care needs to be taken when adjusting the minimum torque set-point. Similarly, pumping for too long will cause the sludge storage tank to be filled with watery sludge. To prevent pump over-runs an adjustable over-run inhibit was added after the trial. Using existing timer clocks to switch power to the RPC, and therefore desludge pump, on and off is also another possible failsafe. Pump over-runs caused by rag trapped in the pump occurred on two occasions. The vulnerability of the system to rag will depend on pump design and the effectiveness of the inlet screens.

The minimum thickness of sludge removed can be controlled and the volume reduced.

Figure 5 shows that the test pump ran for less time (46% less) than the control system. Given that the pumps are fixed speed and a positive displacement type this must have resulted in an equivalent reduction in sludge volume. It’s interesting to note that as the trial progressed and the set-point was raised (leading to thicker sludge being produced) the sludge tank level never inhibited the sludge pumps, in contrast to when using the timer clock control only. Figures 6, 7 and 8 showed that the sludge thickness increased as the torque set-point increased, demonstrating how the average thickness of sludge removed can be controlled. The thickness of the spot samples (Figure 8) was consistently higher than expected from the torque set-point. This is thought to be due to thick sludge from the first phase of the desludge settling in the bucket rather than overflowing into the sludge well. This might have led to thicker sludge in both sample buckets than that produced in the last few pumps of the desludge cycle. This data is still useful in confirming the trend of increasing sludge thickness with torque set-point established by the logger data.

The increase in the maximum sludge thickness as the set-point was raised may be a cause of concern if using pumps that struggle with thick sludge. This can be counteracted by increasing the frequency of desludging.

Allowing the sludge to thicken in the PST may have increased the sludge residence time (SRT). Care must therefore be taken to not set the minimum torque set-point too high, lengthening the SRT and increasing the chance of rising sludge, which would reduce the effectiveness of the PST. This trial was conducted in the autumn and winter of 2011/12 when rising sludge requires a longer SRT than in the summer months.

Reducing the volume of sludge removed did not compromise PST performance.

Figure 9 shows that the initially low sludge blanket and settled sewage suspended solids in the test PST were maintained throughout the trial, even when removing sludge at an average thickness of 6% for nearly two months. The deterioration in performance of the control PST due to inadequate sludge removal (when the motor in the desludge pump failed: data circled in the Figure 9) demonstrates that had the RPC failed the effects would have been clearly seen in the data and underlines the importance of adequate sludge removal.

Economic Evaluation

The cost of installing a RPC system will vary depending on whether the existing panel and pump can be used and whether it is a retrofit or new installation. The extra cost of adding an inverter to any suitable new auto-desludge installation has been estimated and in the experience of the author should always give a favourable payback time. For a retrofit, the cost is dependent on the pump and control system requirements. In the case of the trial site an RPC system was added to both desludge pump control panels in summer 2012 with a payback time of less than two years; based on the thickness of the sludge tankered averaging 4% DS. The data from this trial indicate this target is achievable.

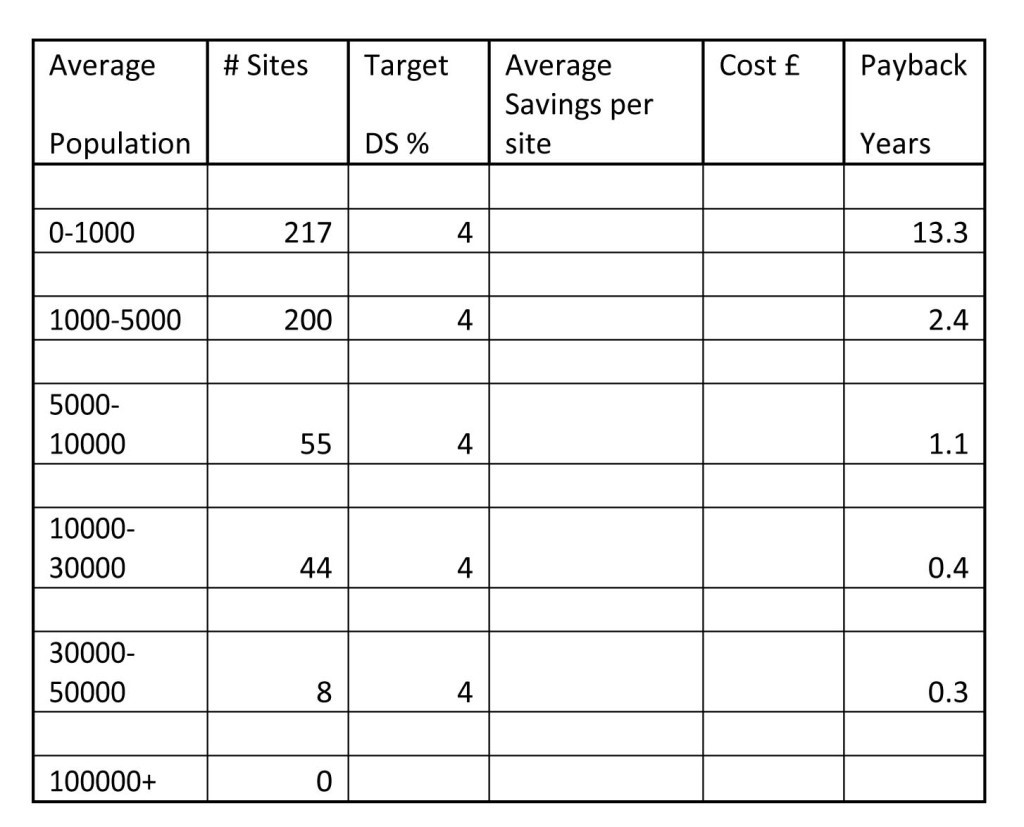

Table 1 summarises an evaluation of where a retrofit installation of the RPC is attractive within Anglian Water trickling filter sites. As expected the payback time reduced with the size of the site. Surprisingly even sites in the 1,000- 5000PE range provided a favourable payback period. This underlines the current high cost of transporting sludges to treatment centres which in the Anglian region is an average distance of 37km each way.

Table 1: Estimation of payback time for trickling filter works

Conclusions

- A useful correlation between pump motor torque and sludge thickness was established.

- The trial demonstrated that using a RPC to control a diaphragm pump desludging a PST is a viable strategy and can lead to a reduction in the volume of sludge removed, by increasing the average %DS.

- No negative impact on PST performance was observed when removing only sludge above 4%DS during the five month trial despite removing the sludge at an average of over 6%DS for a two month period.

- Using the RPC system on new installations is the most attractive option but reasonable payback times are possible even on sites below 5000PE.