Sludge Density Pump Control

Sludge Density Pump Control or Reactive Pump Control (RPC)

Introduction

Sludge is created when a liquid containing solids is settled. Typically, this can be in PSTs (Primary Settling Tanks) or Humus Tanks in sewage treatment works. Alternatively, it can occur in mineral processing plant in clarifiers.

The pumps that take the sludge from the bottom of these tanks have to be controlled. If they do not pump enough, the tanks fill with sludge and solids will carry over into the clarified water. If they pump too much, they will pump thin sludge and this can be costly to handle in further processes. Historically these pumps are controlled on timers. This is inherently an unsophisticated method.

Reactive Pump Control (RPC)

IDS have been controlling sludge pumps with inverters for over 10 years, we have even won awards for it! The idea is simple. When sludge is high in solids, it is thick (viscous) and it requires a greater effort to pump it. When the pump is pumping thin, watery sludge then the effort drops. If nothing else changes, in a positive displacement pump, this change in effort appears as a change in motor torque.

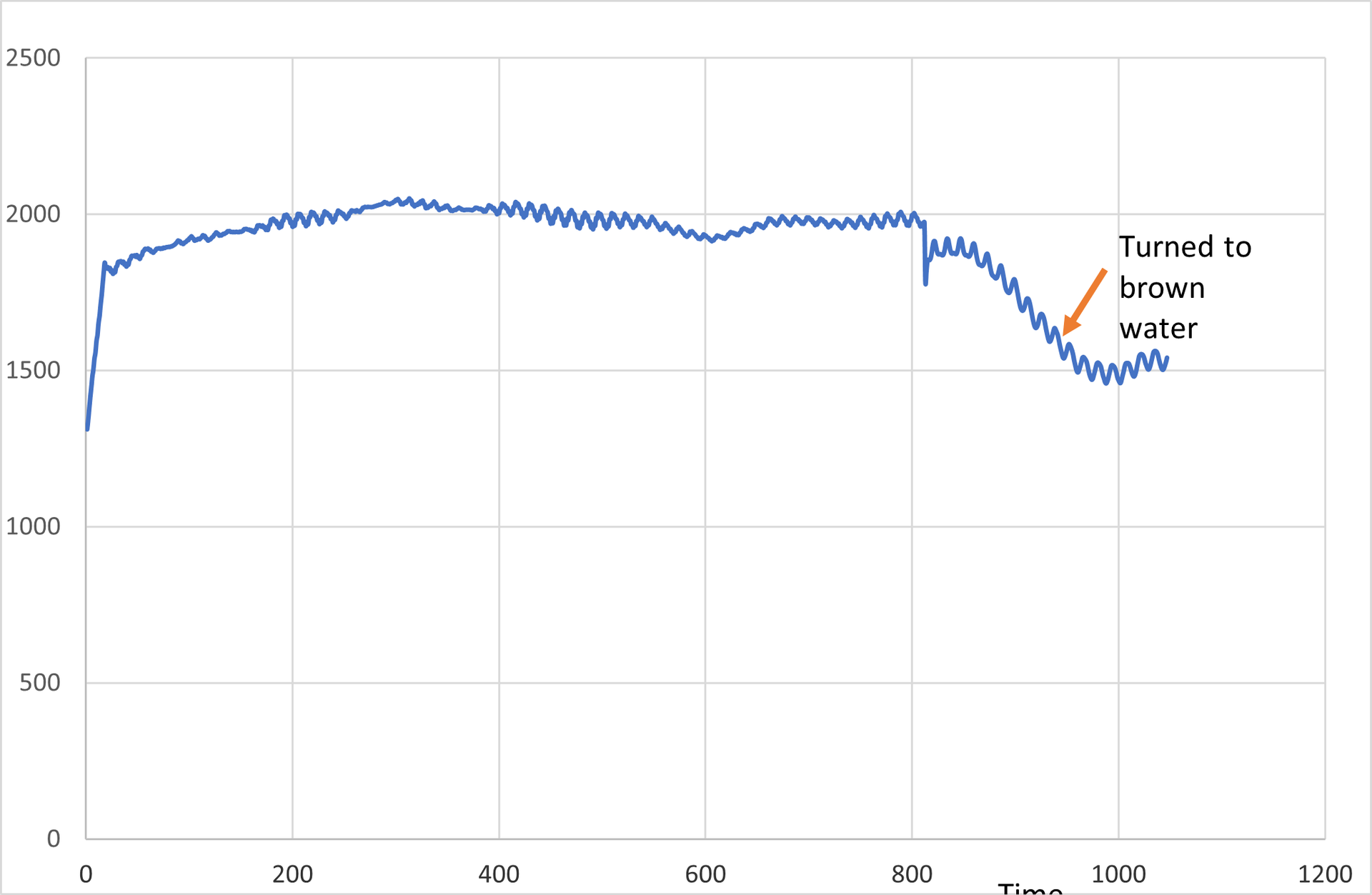

ABB inverters calculate motor torque. Using a simple algorithm and some on-site tests, we measure and process the torque signal then we can programme inverters to only pump when the sludge is thick. When the torque signal drops to a pre-set value, as the sludge becomes thinner, we stop pumping. Typically, we have reduced volumes of sludge pumped by 50% when compared to timer control.

Typical Torque – Time Curve

Benefits of RPC

- Simple sensorless control.

- Very cost-effective solution

- Reduction of sludge volumes by some 50%

- Controlled sludge density

- Adjustable sludge density

- Reduced sludge storage requirements

- Reduced downstream dewatering requirements

- Reduced road tanker costs

- Works with all positive displacement pumps – direct ram, hydraulic ram, lobe, progressive cavity and diaphragm.

Sludge Density Pump Control with IDS

To intelligently and cost-effectively control when the sludge on your site is pumped, talk to our knowledgeable engineers. Call us on 0115 94 1036 or email [email protected]