Selecting Motors And Drives For Explosive Atmospheres

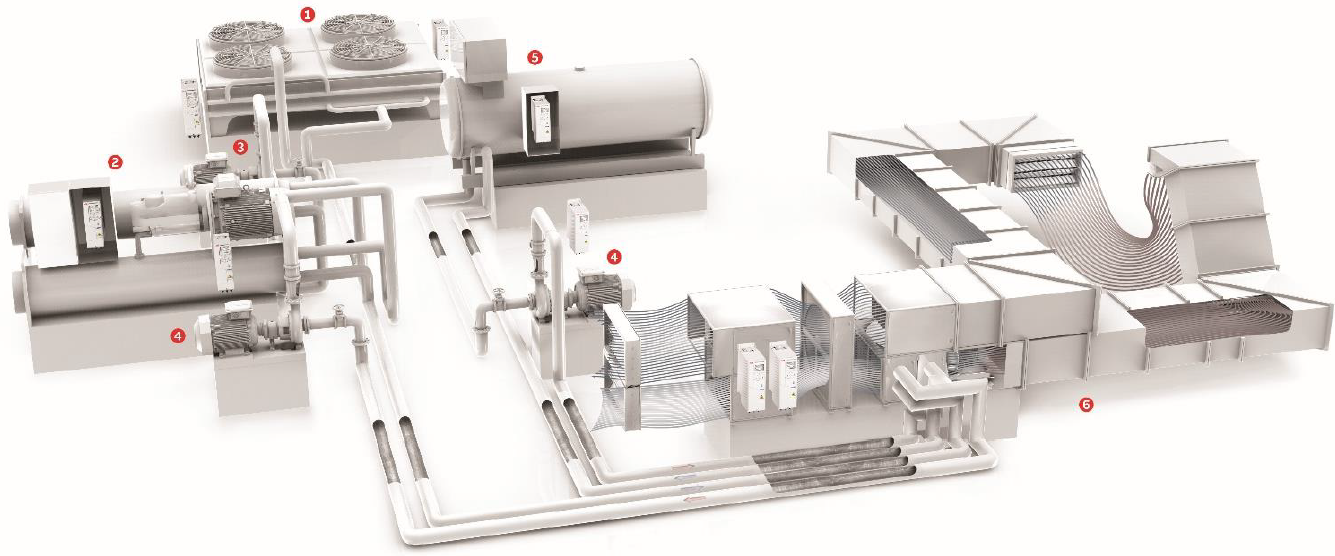

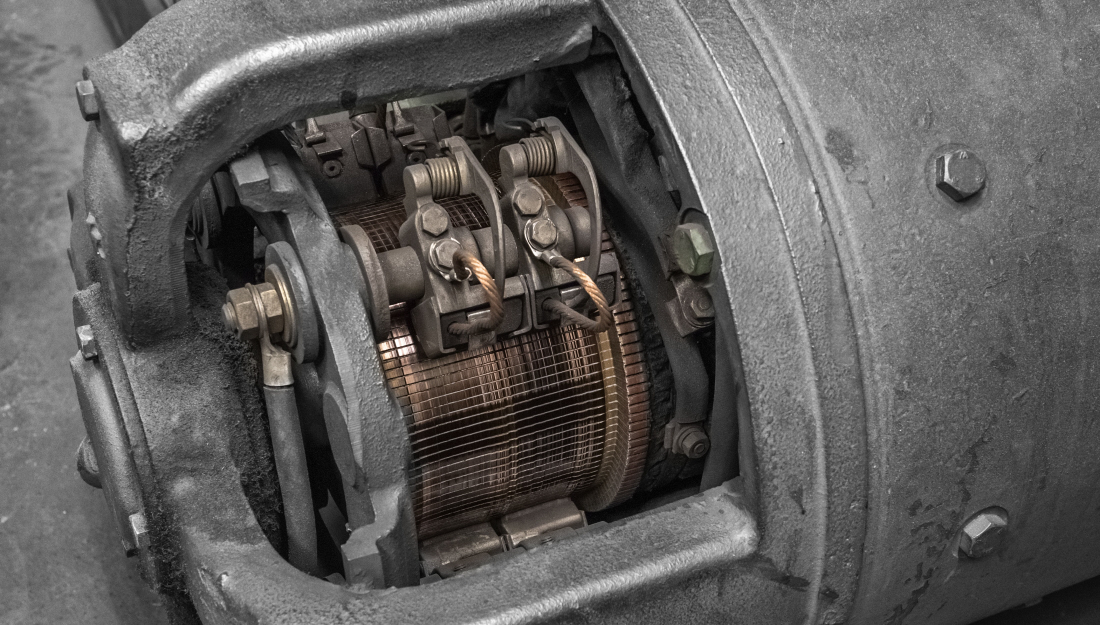

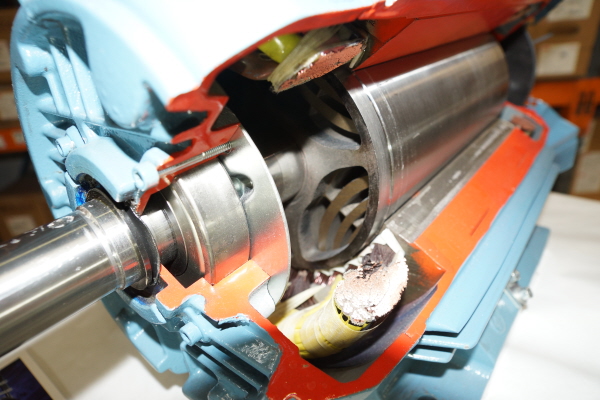

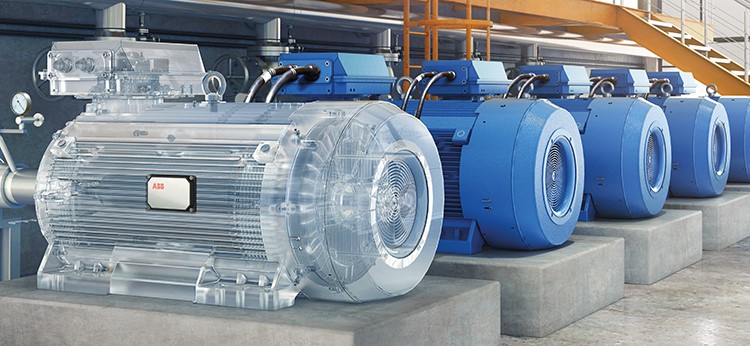

When selecting variable speed drives and motors for potentially explosive atmospheres, the manufacturer’s instructions and recommendations must be followed, otherwise explosion protection measures will be compromised. ABB’s Luciano Santos and Andrew Bould share some advice. Throughout the food and beverage sector, variable speed drives (VSDs) and electric motors are renowned for contributing to productivity improvement and energy efficiency. However, their use needs to be very carefully considered in applications within potentially explosive atmospheres – also…