Choose the Right Drive for your Application

Choosing the right variable-speed drive (VSD) for your application means taking some important factors into account. Critical ones include the expected load, controllability, features and safety.

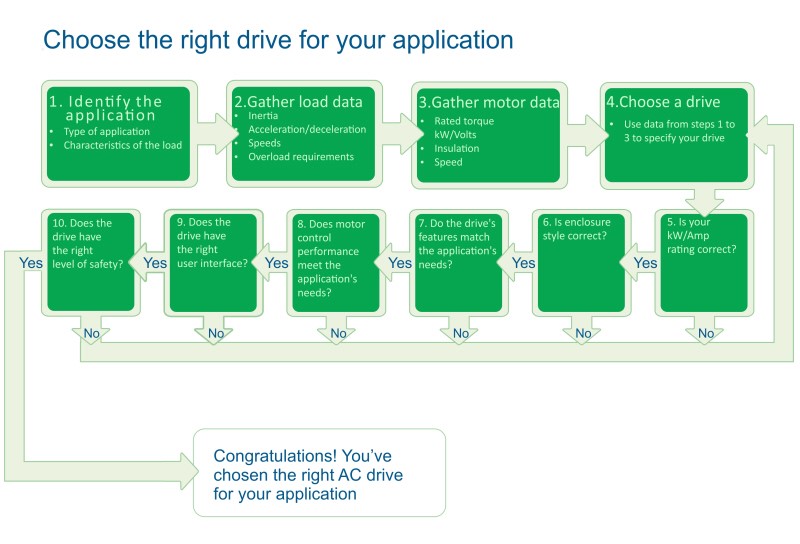

Follow these steps to get the right VSD.

Choose the Right Drive for your Application

1. Identify the application

The first step is to identify the type of application and load. There are essentially three different load types.

Constant torque occurs when fixed volumes are being handled, such as in screw compressors and extruders.

Quadratic load is the most common, used in centrifugal pumps, fans and most mixers.

Constant power is used when a material is being rolled up, or unrolled – the diameter changes while the surface speed remains constant.

There may also be combinations of load types.

Getting the load characteristic wrong could result in oversizing. For a constant load at half speed, a larger motor is needed. In contrast, a fan needs less torque when running at half speed, allowing the selection of a smaller motor frame.

A constant torque drive should have an overload current capacity of 150 percent or more for one minute, while variable torque, variable frequency drives need only 120 percent for one minute.

2. Gather load data

The application’s performance data includes load, system inertia, acceleration and deceleration rates, minimum and maximum speeds and overload requirements.

For example, the true operating speed range is not normally too critical with a centrifugal load, but for a constant torque load it is quite possible to over-frame the motor if it is specified for a greater speed range than necessary.

3. Gather motor data

Knowing the motor’s rated torque, power, voltage, insulation class and speed is critical to choosing the right drive, whether you plan to use an existing motor or a new motor. In the future it will be necessary to match the load to the best efficiency working area of the motor. This may result in a smaller VSD being required.

4. Choose a drive

Once you know the information in the first three steps, you can select a VSD from a manufacturer’s catalogue to meet all the motor requirements.

5. Is kW/amp rating correct?

The next step is to select current from the tables in the manufacturer’s catalogue. Ensure the chosen VSD can supply the correct current to the motor to provide the torque required, including normal and overload conditions.

Select for the best package efficiency region

6. Is enclosure style correct?

Dusty, hot or damp environments or too much vibration can cause VSDs to fail. Always check that the drive is designed for the environment. For instance, all drives carry an IP rating, a measure of its ingress protection.

Don’t specify an IP category too highly, or the filter materials used to improve the protection will deteriorate rapidly.

Other certifications include NEMA, and UL Type enclosures. It is important to match the needs of the application with the right enclosure, either by using a stand-alone VSD with the proper enclosure rating, or putting the VSD inside another enclosure. The VSD must also produce the required current at the application’s altitude and ambient temperature.

7. Do the drive’s features match the application’s needs?

The VSD must have software features that match the application’s needs. Equally vital is hardware, such as inputs and outputs, feedback and communications. If speed, torque and positioning need to be controlled very accurately, a sensorless vector or flux vector variable frequency drive may be needed.

8. Does motor control performance meet the application’s needs?

The VSD must produce the necessary torque at the required speeds. It must also control the speed and torque to meet the requirements of the application.

9. Does the drive have the right user interface?

The user may have to work with the VSD in different ways, altering parameters, choosing from production recipes or altering the times of operation. Make sure the drive has the interface to match how it will be used.

10. Does the drive have the right level of safety?

VSDs can play a major role in ensuring safety in your system. They should only be chosen for safety functions specified by machinery designers – merely selecting safety functions from the catalogue may not be appropriate for all applications.

Stick to these tips and you should get the VSD you need, while keeping capital costs and operating expenses to a minimum.

If you need further assistance choosing the right drive for your application then contact our ABB Inverter specialists on 0115 944 1036 or email [email protected]