Motor Drive Package For Cooling Towers Eliminates Gearbox Failure

Gearbox failure on cooling tower fan applications is eliminated with an ABB motor-drive package designed specifically for such hot and humid operating environments.

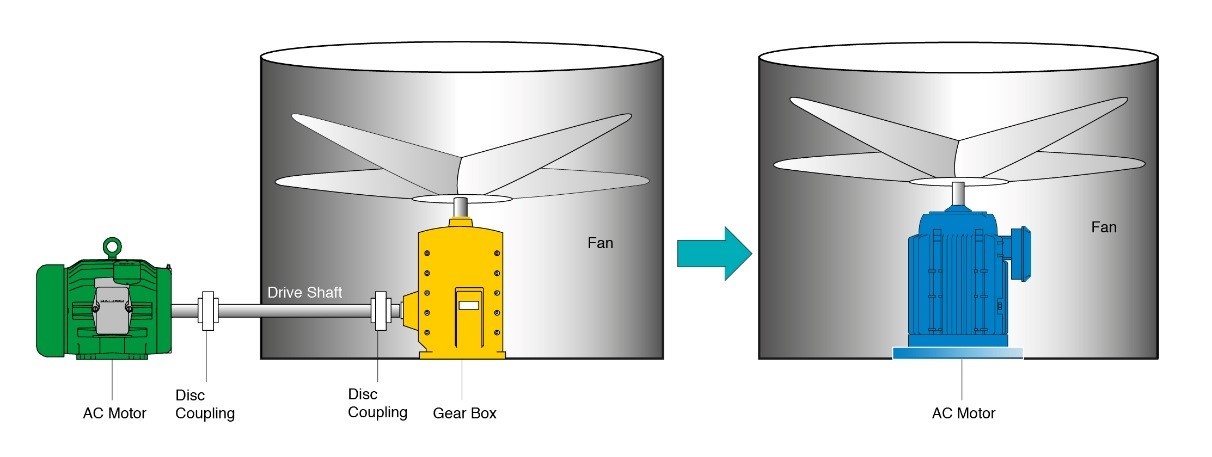

A traditional cooling tower drive system consists of an AC motor, a gearbox, pillow block bearings and shaft couplings to achieve the air flow required. Any one of these mechanical components runs the risk of failure through regular daily use, together with the extreme environment. Fitting a permanent magnet motor, with variable-speed control, directly coupled to the fan eliminates all of these mechanical devices, thereby reducing purchase and maintenance costs.

Significant energy savings, typically greater than10 percent will also be achieved through the elimination of the gearbox and drive train components. Even greater energy savings will be achieved by using the variable-speed drive to reduce speed when the tower is at lower load.

The ABB motor-drive package for cooling towers comprises an ABB permanent magnet motor with an ABB industrial drive, ACS880. The ABB drive is used to establish an optimum speed set point and allows a trickle current to flow to the motor to prevent the fan from wind milling when not in operation.

Motor Drive Package For Cooling Towers Eliminates Gearbox Failure

Together, the motor and drive combination delivers precise fan control without the need for a gearbox, even under low load or speed conditions often experienced in cooling tower applications.

ABB’s RPM AC permanent magnet motor has a high power and torque density ratio which is needed to achieve the sustained low speed required for cooling tower operation. It is designed to retrofit into existing gearbox footprints within the cooling tower to allow swap-out in less than six hours.

The motor has a low temperature rise, thereby providing cooler running that extends its life. Eliminating the gearbox from the cooling tower system increases efficiency levels as the power from the motor is transferred directly to the fan with virtually no losses.

Removal of the gearbox and drive train will also yield significant reductions in acoustic noise from the tower.

ABB is a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 150,000 people.

IDS are an ABB AVP (Authorised Value Provider) and are able to specify, supply, install, commission, service and repair ABB inverters and associated products. To enquire about the IE4 Motor and inverter package then call us now 0115 944 1036 or email [email protected]